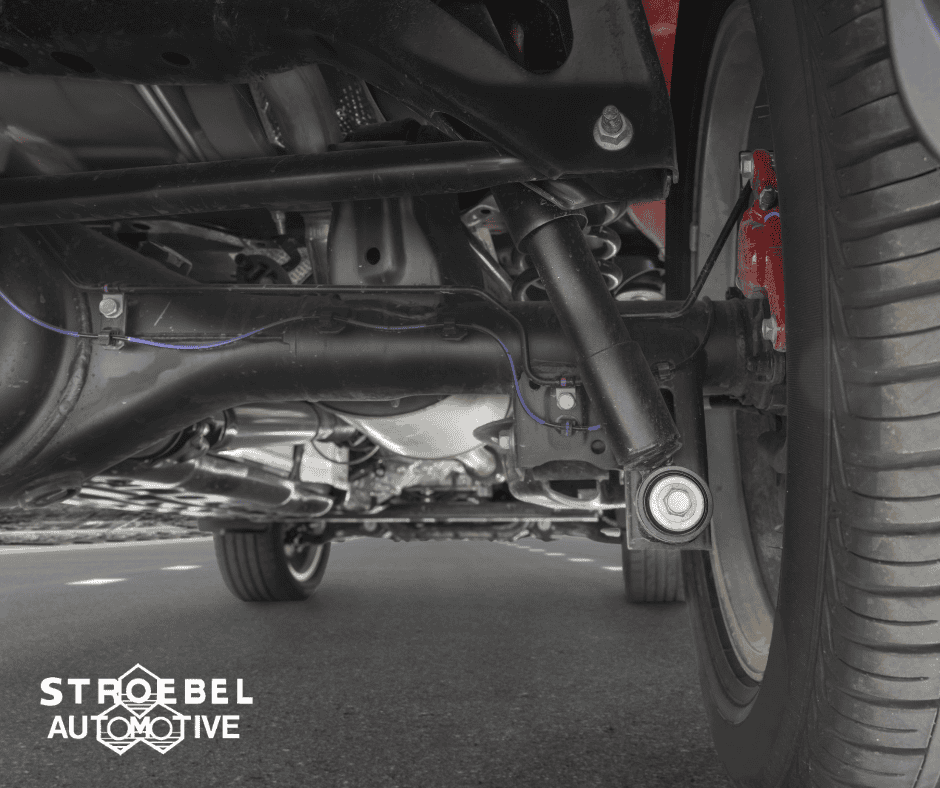

The drive train system of a vehicle is a complex network of components that work in unison to deliver power from the engine to the wheels, enabling the vehicle to move. This system includes key elements such as the transmission, driveshaft, differential, and axles, each playing a crucial role in ensuring smooth and efficient operation. Understanding the intricacies of the drive train system, common problems that may arise, potential repairs, and preventive recommendations can help maintain a vehicle’s longevity and performance.

Components of the Drive Train System

The drive train system begins with the transmission, which is responsible for converting the engine’s power into torque that the wheels can use. There are different types of transmissions, including manual, automatic, and continuously variable transmissions (CVT), each with its unique mechanisms. The driveshaft then transfers this torque from the transmission to the differential. The differential plays a critical role in allowing the wheels to rotate at different speeds, especially when the vehicle is turning. Finally, the axles connect the differential to the wheels, transmitting the final output to the tires.

Common Drive Train Problems

Over time, the drive train system can develop issues due to wear and tear, lack of maintenance, or external factors. Some of the most common problems include:

- Transmission Slipping or Hard Shifts: This can occur in both manual and automatic transmissions. Symptoms include erratic shifting, delays in gear engagement, or the transmission slipping out of gear. Causes may include low transmission fluid levels, worn-out clutches, or damaged gears.

- Driveshaft Vibrations: A damaged or unbalanced driveshaft can cause vibrations that are felt throughout the vehicle, especially at higher speeds. This issue could be due to worn-out U-joints, a bent driveshaft, or imbalanced components.

- Differential Noise: Whining, grinding, or clunking noises from the differential can indicate worn-out gears, low differential fluid, or damaged bearings. Left unaddressed, these issues can lead to costly repairs.

- Axle Problems: Broken or damaged axles can cause the vehicle to lose power to the wheels or even make the car undrivable. This is often caused by accidents, excessive wear, or corrosion.

Repairs and Solutions

Addressing drive train problems promptly is essential to avoid further damage and more expensive repairs. Some common repair solutions include:

- Transmission Repairs: Depending on the issue, transmission repairs can range from simple fluid changes to more complex tasks like replacing the clutch in a manual transmission or rebuilding the transmission in severe cases. Regular maintenance, such as fluid changes, can prevent many transmission problems.

- Driveshaft Balancing and U-joint Replacement: If the driveshaft is causing vibrations, it may need to be balanced or have its U-joints replaced. In some cases, the entire driveshaft might need replacement if it’s bent or severely damaged.

- Differential Service: Addressing differential noise often involves replacing worn-out gears or bearings. Regularly checking and changing differential fluid can prevent many issues from arising.

- Axle Replacement: If an axle is damaged, replacing it is often the only solution. Regular inspection of the axles, especially after off-road driving or accidents, can help identify issues before they become severe.

Recommendations for Maintenance and Longevity

Preventive maintenance is key to ensuring the longevity of the drive train system. Here are some recommendations:

- Regular Fluid Checks and Changes: Transmission and differential fluids should be checked regularly and replaced as per the manufacturer’s recommendations. Keeping these fluids at the right levels and conditions is crucial for the smooth operation of the drive train.

- Routine Inspections: Regularly inspect drive train components, especially if the vehicle is subjected to heavy use or off-road driving. Catching issues early can prevent them from escalating.

- Addressing Issues Promptly: If any signs of drive train problems arise, such as unusual noises, vibrations, or shifting issues, have the vehicle inspected by a professional immediately. Delaying repairs can lead to more extensive damage and higher repair costs.

- Proper Driving Habits: Avoid aggressive driving, which can put extra stress on the drive train components. Smooth acceleration, braking, and steering can extend the life of the drive train system.

The drive train system is vital to a vehicle’s performance and reliability. Understanding its components, common problems, and the importance of regular maintenance can help keep your vehicle running smoothly for years to come. Contact Stroebel Automotive if you have concerns about your drive train system or any other concerns about your vehicle.